FRP molded grating

FRP molded grating

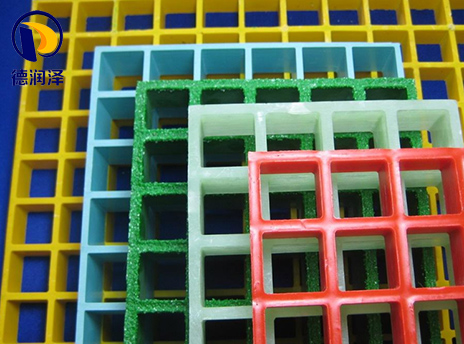

Glass fiber reinforced plastic (referred to as FRP) molded grid is a kind of unsaturated polyester resin (including isophthalic, orthophthalic, vinyl, phenolic, bisphenol A, etc.) as the matrix, With glass fiber roving (medium-alkali or alkali-free) as the skeleton, it is a plate-shaped material with a certain opening rate made by a special process on a custom mold. The grid is made of glass fiber interlaced weaving and resin casting as a whole. The fiberglass grid has the following characteristics:

1. The interlaced weaving of glass fibers and the full penetration of resin make the grille more resistant to corrosion.

2. The overall structure of the grille distributes the load evenly, which is conducive to the uniform stress of the grille installation and its installation support structure.

3. The glossy surface and italic grid surface of the grid make the grid self-cleaning.

4. The concave surface of the grid makes the grid have anti-slip performance, and the anti-slip effect of the sanded surface is better.

Properties of Molded Gratings

(1) Corrosion resistance of various chemical media, not easy to rust, long service life, low maintenance.

The grid produced by our company is a non-metallic material. It is different from the traditional metal grid. Under the action of chemical media, it will not rust due to electrochemical corrosion, and will not damage the structure of the material.There is no need for regular or irregular inspection and maintenance, it will not cause the plant to stop production, and it will not cause a series of unforeseen accidents due to the existence of many invisible factors like metal grilles. At the same time, it is also different from wood and other materials that will corrode and mildew. It is an upgraded product of traditional iron, wood, cement and other materials.

(2) flame retardant

The company's specially designed formula can meet the requirements of the project for fire protection. The company's products have passed the ASTME-84 flame retardant test and have good flame retardant and fireproof performance.

(3) Insulation, flame retardant, non-magnetic

(4) It has slight elasticity, which can reduce the fatigue of personnel and improve work efficiency

(5) Lightweight, high strength, and easy to cut and install

Because it is composited by resin and glass fiber, its density is only 1/4 of that of iron and 2/3 of that of aluminum, but its relative strength is higher than these metals. Its light weight can greatly reduce the foundation support, thereby reducing the material cost of the project. It is easy to cut and install, without hot fire and large lifting equipment, and only requires a small amount of labor and electric tools, which greatly reduces the installation cost.

(6) The color is uniform inside and outside, and the color can be chosen arbitrarily. Colors can be customized according to customer requirements to improve the environment of the production site.

(7) It has good comprehensive economic benefits

(8) Strong designability, flexible and diverse sizes, and stable dimensions

The company can customize products according to customer requirements, such as different cell sizes, different dimensions, different load requirements, etc. It can meet the requirements of customers to the greatest extent, and can minimize the loss caused by cutting, thus saving costs for customers.

Applications

This product can be used in the following places: chemical industry, paper industry, power plant, sewage treatment plant, food processing plant, smelter, mine, salt field, nuclear power plant, battery factory, etc. It can be used as: sidewalks, bridge slabs, industrial floors, operating platforms, trench covers, pallets, guardrails, fences, shelves, isolation belts, green walkways, floor steps, etc.