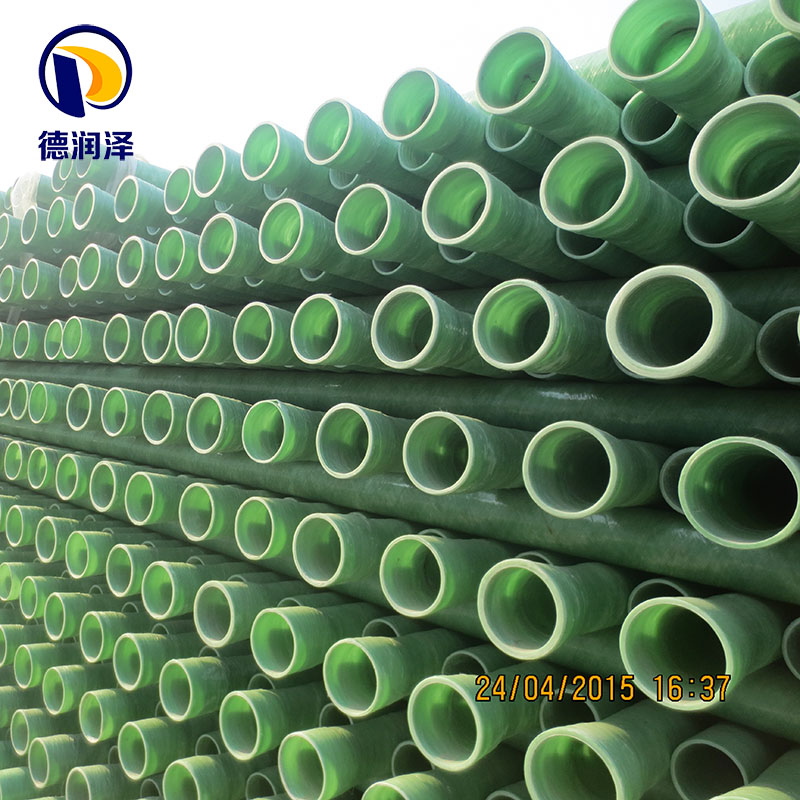

FRP cable tube

FRP cable tube

FRP cable protection pipe is a kind of pipe formed by computer-controlled winding process or pultrusion process with resin as matrix, continuous glass fiber and its fabric as reinforcement material.

Features:

1. High strength, suitable for direct burial under the roadway, no need to add a protective layer of suspected soil, which can speed up the construction progress of the project.

2. Good toughness, able to resist damage caused by external heavy pressure and foundation settlement.

3. It has good electrical insulation, flame retardant and heat resistance, and can be used for a long time at a high temperature of 130 degrees without deformation.

4. Corrosion resistance, long service life, can resist the erosion of various corrosive media such as acid, alkali, salt and organic solvents, and its service life can reach 50 years.

5. The inner wall is smooth and does not scratch the cable. Rubber sealing ring socket joint, easy to install and connect, and adapt to thermal expansion and contraction.

6. The specific gravity is small, the weight is light, one person can lift it, and two people can carry out the installation, which can greatly shrink.

7. Short construction period, reduce installation costs, and avoid long exposure time of road excavation, affecting urban traffic order and other issues.

8. No electrical corrosion, non-magnetic. Unlike magnetic materials such as steel pipes, after eddy currents are generated, the cables will be heated and damaged.

9. Wide range of applications: FRP cable protection tubes are suitable for use as protective tubes when cables are laid underground, and are also used in high-demand occasions such as cable bridges and river crossings. Using the matching professional pipe pillow combination, it can form a multi-layer and multi-row multi-pipe pipe arrangement.

Product Usage:

FRP cable protection tubes can meet various specific requirements of users, and can be applied to various site areas such as muddy soft soil construction areas, collapsible loess areas, lake Haidian areas, and areas with high-depth chemically corrosive media. The matching special pipe-pillow combination can be used to form a multi-layer and multi-row multi-pipe pipe arrangement. Typical application areas:

(1) Urban power grid construction and renovation projects.

(2) Urban municipal renovation projects.

(3) Civil aviation airport engineering construction.

(4) Construction of industrial parks and communities.

(5) Construction of traffic, road and bridge projects.